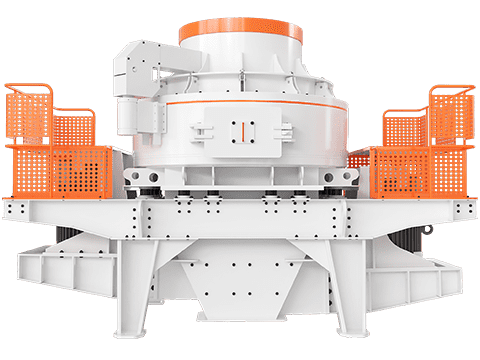

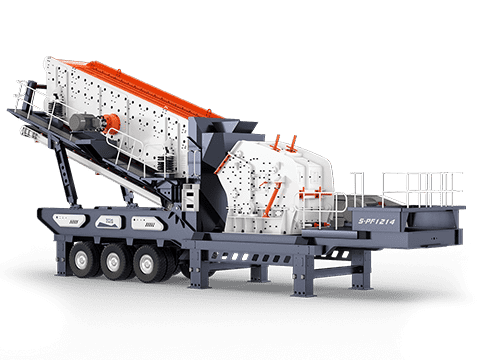

The cost-effectiveness of sand making equipment is not necessarily due to its low price, but rather its high cost-effectiveness when purchasing sand making equipment. The technical content corresponds to the equipment price. For example, if the sand making machine adopts these technologies, is there a significant difference in the cost of the technical process and the price of the equipment, so that it will not be deceived when purchasing. And the quality of the sand making machines we produce can be completely assured, ensuring the quality of each sand making machine. As they are directly supplied by the manufacturer, the price can also meet the needs of the vast majority of users. Moreover, every sand making machine equipment must pass the inspection before it can be sold to the market, so the quality is reliable and the price is excellent. Is the sand making machine equipment suitable for the sand making machine you purchased compatible with the product you purchased? We know that this is a type of calcium carbonate mineral, which is more common than calcium carbonate. Their crystal shapes vary, and they can be clustered into crystal clusters, or granular, blocky, fibrous, earthy, etc. Due to their different shapes, processing is more complex. Therefore, the sand making machine we purchase must meet the material sand making requirements. Especially suitable for making sand from complex materials. Whether the production efficiency reaches 300 sand machines per hour, the first thing to consider is how much sand can be produced per hour. Firstly, it is for your future interests, and secondly, it is important to know when to return the cost. What is the output of a sand making machine to calculate. Large sand making machine manufacturers have clearly stated that their production capacity should reach over 300 per hour. Otherwise, buying this device will not be cheap. The particle size of finished materials can be adjusted by adjusting the lining plate and adjusting the particle size. The powder output can be adjusted by adjusting the gap between the hammer heads of the machine. If necessary, auxiliary production equipment such as powder selection machines and ventilation equipment can also be added, which can greatly improve production efficiency. This point requires special attention when purchasing.

Consultation hotline:

Consultation hotline:

MessageIf you have any questions, please leave a message here and let us know. We will contact you promptly!

MessageIf you have any questions, please leave a message here and let us know. We will contact you promptly! 产品推荐

产品推荐

Online Service

Online Service By Telephone

By Telephone Message Consultation

Message Consultation